Bredent Pi-Ku-Plast HP 36 Monomer

Made in Germany

Monomer for the Pi-Ku-Plast resin coping system.

The Pu-Ku-Plast HP36 has exceptional material properties such as perfect contouring characteristics and no slumping provide the precondition for top-quality casting results.

Available in five different colors.

Has a contraction value of just 0.036 %.

Sets quickly.

Perfectly suitable for the fabrication of resin dies or resin copings in the double crown technique.

100 ml per bottle

Made in Germany

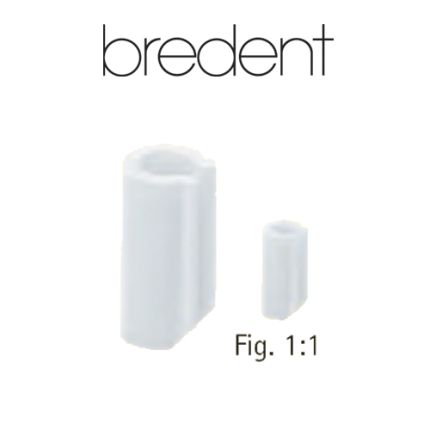

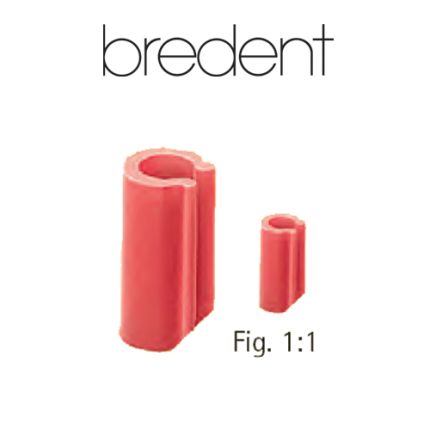

Optimum contouring properties, will not slump. Available in 5 different transparent colors to allow the thickness to be checked and to contract well within the wax. When used with the Pi-Ku-Plast separating agent, resin inner copings can be base for producing milled restorations. Ideal for connecting bar sections for soldering.

Due to the multigrain design, Pi-Ku-Plast absorbs less monomer and therefore has less shrinkage. Various grain sizes shift into the gaps of each other for a compact, sturdy application. The burnout is clean and complete. In burnout, Pi-Ku-Plast does not expand but collapses. This puts no internal stress in the casting ring, resulting in a clean, stress-free casting.

Wet the brush with the Pi-Ku-Plast monomer. The amount and firmness of the portion can be controlled by the amount of monomer on the brush and the time it is immersed in the polymer. Because the material does not have to be pre-mixed, no resin is wasted due to over mixing the two components. After using, the brush is cleaned in the cleaner and the vessels are covered to keep the Pi-Ku-Plast in good working condition.

| Pi-Ku-Plast HP 36 Monomer, Red, 100 ml |

Five translucent colors simplify control of layer thicknesses so that reworking is minimized. 100 ml bottle