Ivoclar IPS Classic Powder Opaquer Liquid

Made in Liechtenstein

The powder opaquer has been coordinated with fusable alloys and is suitable for the masking of alloys in the CTE range of 13.8 to 15.2 (25 to 500°C).

It ensures the establishment of a reliable bond with the layering materials during the subsequent veneering procedure.

The alloy frameworks can be fabricated in the casting technique, CAD/CAM technique or laser melting technique.

IPS Classic Powder Opaquer Liquid

A new powder opaquer for the metal-ceramic layering technique affords flexibility regarding different application techniques in the dental lab.

The new IPS Classic V Powder Opaquer was developed using a new production method. Users benefit from its great flexibility in application techniques as well as from a fast and efficient veneering process. These advantages are based on the very high application stability of the powder opaquer during application.

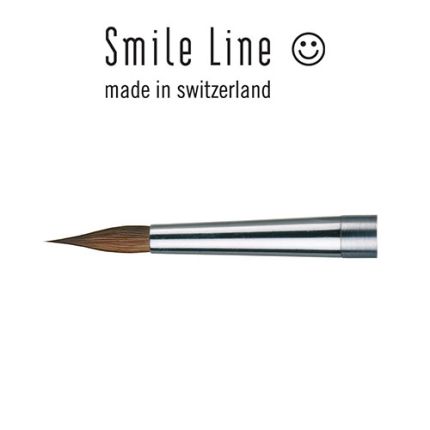

The powder opaquer can be applied with either a brush or instrument or by means of the spray-on technique. Thanks to the material’s homogeneous consistency, the frameworks are masked with only a very thin, colour-stable layer, ensuring smooth surfaces without any bubbles or cracks. Furthermore, the separately packaged powder liquid provides for a consistent quality. The IPS Classic V Powder Opaquer complements the IPS Classic V metal-ceramic portfolio.

The patented metal-ceramic material, IPS Style offers dental labs maximum efficiency, easy handling and life-like esthetics. This is the first material in the history of dental ceramics to contain oxyapatite crystals. These crystals reflect a high amount of incident lighting and provide restorations with a natural-looking depth.