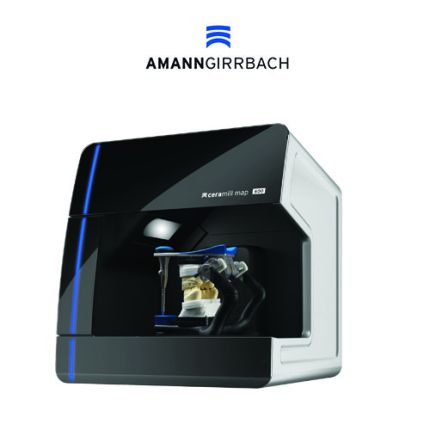

Amann Girrbach Ceramill Mikro IC

This compact 4-axis milling unit extends in-house fabrication of conventional laboratory indications to include the option of wet grinding/milling. Titanium abutment blanks can also be processed with this unit in the same way as composites, hybrid and glass ceramics.

Manufactured in Austria

This compact 4-axis milling unit extends in-house fabrication of conventional laboratory indications to include the option of wet grinding/milling. Titanium abutment blanks can also be processed with this unit in the same way as composites, hybrid and glass ceramics.

The monocoque design, typical for Ceramill units, gives the machine stability and torsion resistance despite its small footprint. In combination with the solid design of the axis system and quiet-running, powerful high-frequency spindle the respective milling strategies can be precisely transferred to the blank using high feed rates.

This is particularly effective when grinding in the “carving mode”. This innovative grinding process reduces the processing times of single blocks by up to 60%.

Benefits:

- High-performance processing thanks to DNA milling/grinding strategies

- “Carving mode” reduces the processing times of single blocks by up to 60%

- Solid design enables the highest degree of precision with maximum feed rates

- Special holder design ensures easy handling and accuracy when processing hard materials (titanium, glass ceramics etc.)

Technical Data

- Axes: 4

- Processing mode: Wet

- Tool management: 8-compartment tool changer, management of replacement tools

- Dimensions: 465/580/585 (mm)

-Weight: 70kg

- Power Output: 750W

- Motor Speed: 100,000 rpm

- Compressed Air: 50 L/min. at 6 bar